A value-engineered HVAC system reduces duct costs, right-sizes equipment, and improves energy efficiency for affordable comfort.

The Push for Smarter HVAC

Heating, ventilation, and air conditioning (HVAC) systems account for some of the highest energy expenses in a home. With efficiency standards rising, homeowners and builders face a choice: invest in expensive high-efficiency units or redesign systems for smarter performance. Value-engineered HVAC systems provide the latter option.

By focusing on layout and design rather than oversizing equipment, this approach lowers installation costs, reduces utility bills, and improves comfort. Instead of relying on outdated “rules of thumb,” value engineering integrates HVAC planning into the overall home design.

Principles of Value Engineering HVAC

Value-engineered HVAC revolves around several core practices:

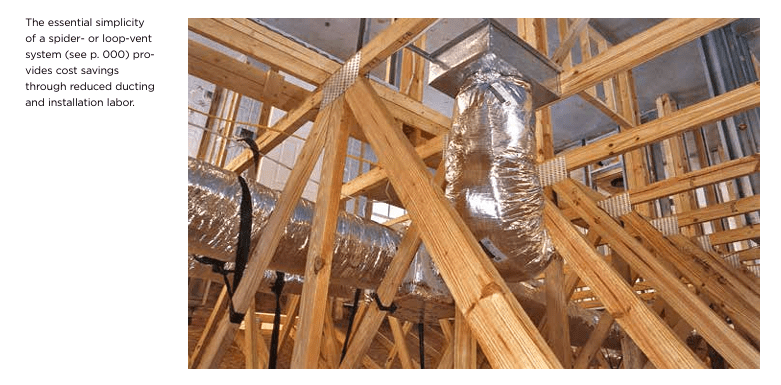

Centralize equipment placement – Locating the furnace or air handler in the center of the home reduces duct length and ensures more even airflow.

Keep ductwork inside conditioned spaces – Ducts in attics or crawlspaces leak energy. Placing them indoors minimizes loss.

Simplify supply and return systems – A central return with transfer grilles between rooms is more efficient than duplicating ductwork for every space.

Right-size equipment – Smaller, correctly sized units work more efficiently than oversized systems that waste energy.

These steps not only cut upfront costs but also improve long-term performance.

Cost Benefits of Smarter Design

A well-engineered duct system can reduce distribution costs by 20–30%. Properly sized equipment adds another 30–50% reduction in utility bills. Builders report that total HVAC costs per home can drop by as much as $1,500, while homeowners benefit from annual energy savings of 20–50 cents per square foot.

The takeaway is clear: efficiency doesn’t depend on buying the most expensive furnace or air conditioner. Smart design delivers comfort at a fraction of the price.

The Problem with Oversizing

HVAC contractors often install larger systems “just in case.” This practice backfires. Oversized units cycle on and off too quickly, creating uneven temperatures, poor humidity control, and higher energy bills.

If you must choose between rounding equipment size up or down, engineers recommend rounding down. A 10,000-Btu reduction can save hundreds in equipment costs while improving efficiency.

Design Strategies That Work

Avoid conditioning small spaces like bathrooms or utility rooms unless necessary.

Place supply registers on interior walls instead of under windows, since modern insulation eliminates the need for “blanket heating.”

Dedicate 10 sq. ft. of floor space for equipment placement to keep systems inside the building envelope.

These decisions may seem minor, but they deliver long-term savings.

Value-engineered HVAC is about smarter—not bigger—systems. By rethinking duct layouts, sizing equipment properly, and keeping everything within the building envelope, builders and homeowners can achieve affordable, efficient comfort that lasts.

Want to explore more strategies like this? Check out my book for a deeper guide to HVAC planning, insulation, and affordable home design.

Also read: Affordable Plumbing Fixtures: Save Money Without Sacrificing Quality